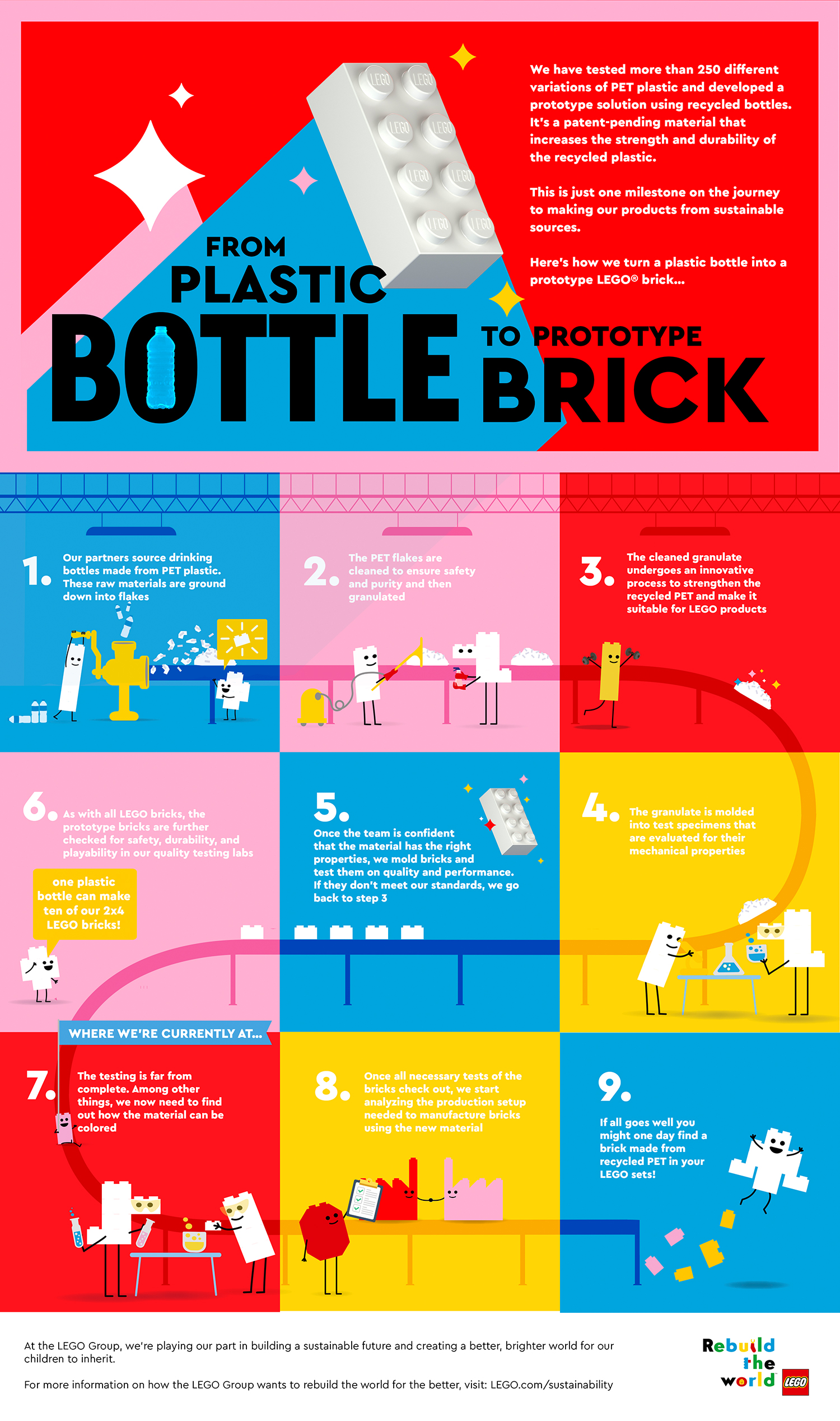

LEGO has unveiled a prototype LEGO brick made from recycled plastic, as part of its journey to make LEGO products from sustainable materials. The new prototype was made from used plastic bottles acquired from suppliers in the United States. A one-liter plastic bottle supplies enough raw material for around 10 2×4 Lego bricks.

LEGO trialed over 250 formulations of recycled plastic to create a brick that complies with the company’s quality, safety and play requirements. Its “clutch power” – the ability to snap onto other pieces of LEGO – means that it is compatible with Lego’s standard bricks.

The patent-pending material formulation increases the durability of PET to make it strong enough for LEGO bricks. The innovative process uses a bespoke compounding technology to combine the recycled PET with strengthening additives.

The recycled prototype brick is the latest development in making the LEGO Group’s products more sustainable. In 2020, the company announced it will begin removing single-use plastic from its boxes. In 2018, it began producing elements from bio-polyethylene (bio-PE), made from sustainably sourced sugarcane. Many LEGO sets contain elements made from bio-PE which is perfect for making smaller, softer pieces such as trees, branches, leaves and accessories for minifigures. Bio-PE is not currently suitable for making harder, stronger elements such as the iconic LEGO bricks.

Lego now plans to rigorously test and develop the prototype brick before assessing whether to move the rPET into production. Tests will determine whether the patent-pending material formulation is strong and durable enough for Lego bricks.

“We need to work on how we color the material consistently and look into the different shapes it can be molded into,” Lego told urdesign. “Then we will be in a position to assess whether to move into pilot or trial production.”

“Any new materials we use must live up to the high quality and safety standards as those we apply to our existing products – this includes the product durability,” the brand said.

The LEGO Group’s focus on sustainable material innovation is just one of several different initiatives the company has in place to make a positive impact. The LEGO Group will invest up to US $400 million over three years to 2022 to accelerate its sustainability ambitions.

“For us, the challenge comes from needing materials that can be moulded to the accuracy of a hair width to ensure bricks produced today fit with those made over 60 years ago, while being durable and safe enough to be handled by children day-in, day-out,” said Lego.

“Lego bricks are designed to be safe and durable enough to be passed from generation to generation rather than being thrown away. Despite this, we are committed to making our products from more sustainable materials in the future,” it continued.

“To do so, we need to invent entirely new materials, as existing sustainable materials do not meet our safety and quality requirements.”